Type:

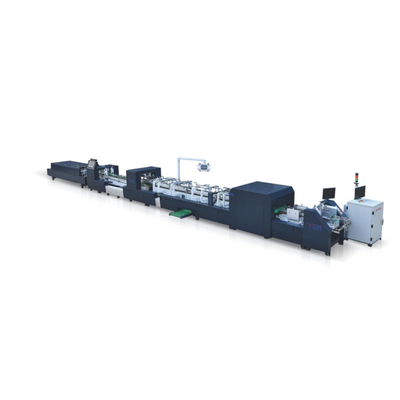

Gluing Machine

Applicable Industries:

Machinery Repair Shops, Food & Beverage Factory, Food & Beverage Shops, Advertising Company, Packaging and printing industry, Gift box manufacturer, Carton manufacturer, Drug packaging box

Showroom Location:

Viet Nam, India, Mexico, Thailand

Video outgoing-inspection:

Provided

Machinery Test Report:

Provided

Marketing Type:

YDM JC

Warranty of core components:

1 Year

Core Components:

PLC, Engine, Motor

Condition:

New

Application:

Food, Beverage, Medical, Chemical, Machinery & Hardware, Textiles

Packaging Type:

Cartons, Bags, Belt

Packaging Material:

Plastic, Metal, Wood

Automatic Grade:

Automatic

Driven Type:

Electric

Voltage:

380V

Dimension(L*W*H):

20000 (L) *1550 (W) *1600(H) mm

Weight:

8500 KG

Warranty:

1 Year

Key Selling Points:

Full Automatic

After-sales Service Provided:

Engineers

speed:

400m/min

Box type:

one side,lock bottom,four corner,six corner with inspection function

Min.spot defect size:

0.1mm2(contrast>15)

Min.Linear Defect size:

0.15mm*5mm(contrast>15)

Overprint detection accuracy:

±0.15mm

Die-cutting detection accuracy:

±0.3mm

Power consumption:

19KW, 380V AC ,50Hz,3P

Max inspection speed:

200m/min

code inspection:

Code repeated, code missing,code mistake

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!  ¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!